Dual Column Pole drilling line to drill up to 2" holes

This custom-built machine offers exceptional capability and precision for drilling up to 2" holes in poles up to 82 feet in length and from 6 to 30 inches in diameter.

Specifications

Key Features of the United Precision Dual Column CNC Drilling Machine:

- Independent Dual Columns: Each column operates under full 4-axis CNC control, enabling simultaneous or separate operations with outstanding flexibility.

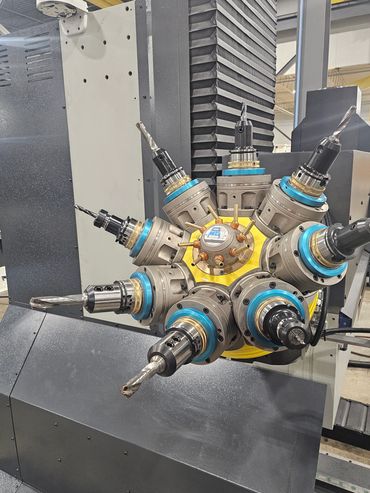

- Rapid Tool Change: A high-speed 8-position revolving turret enables tool changes in just 2 seconds, minimizing cycle times.

- Massive Drilling Capacity: Engineered to drill holes up to 2" in diameter into poles as long as 82 feet.

- Laser Material Detection: Smart sensors identify material position for rapid and safe approach.

- Breakthrough Detection: Ensures precise control and feedback when drills exit the material.

- Automated Material Handling: Features fully automatic loading and hydraulic clamping of poles.

- Fanuc 31i Series CNC Control: A proven industry-standard for high-performance multi-axis machining.

- 13 CNC-Controlled Axes: Full multi-axis synchronization for drilling, tapping, and pocket milling.

- Self-Centering Floating Chuck: Automatically adjusts to chuck poles ranging from 6” to 18” in diameter, without manual intervention.

- Offline Programming: Allows seamless job setup and programming without interrupting machine operation.

- Chip Conveyance System: Efficient chip management for extended unattended operation.

- Tapping & Pocket Milling Capability: In addition to drilling, the machine performs high-precision tapping and pocket milling. Rigid 5-axis machine designed for accurate single-piece production

Photo Gallery

Video

Check out this great video

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.