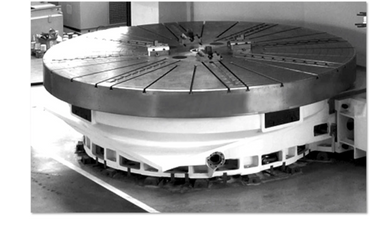

Fixed Rotary Table Series (FRT)

Fixed Rotary table under a moving Gantry, allowing for turning and milling on a single machine. A full Multi Process machine for heavy duty Turning and Milling.

Specifications

Rigid 5-axis machine designed for accurate single-piece production

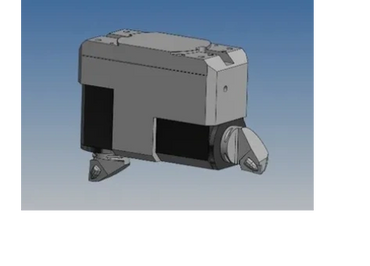

5-axis machining with 2-axis fork-type milling head or optional indexing head.

Moving Gantry machine for high rigidity and accuracy of a Fixed Bridge and Rotary table, converting the machine in a VTL or Multi Process Machine.

Feed rates up to 800 ipm for stable production

Unique closed design of the cross-beam and cross-slide (box-in-box design)

Hexagon ram-type milling unit

Stationary work piece for the highest surface qualities

Very compact machine with large working area utilizing minimal floor-space

High productivity - roughing and finishing operations in one set-up

Ergonomic configuration - floor-level access to the machine tool interior

Tooling and Spindle taper to customer's requirements.

Tool Changer capacity 30 (Optional 40 - 120 tools)

Dual Chain Link Chip Conveyors

4 feet of travel between spindle nose and clamping surface (5 to 6 feet optional)

10 to 100 Ton Table load capacity

Positioning accuracy 0.0008"/39.37"

Repeatability 0.0004/39.37".

Photo Gallery

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.